Self-regulating heating cables or electric heat tracing tapes are innovative solutions designed for heating, temperature maintenance, and freeze protection in a wide range of industrial, commercial, and residential applications.

Manufactured with advanced technology and high-quality materials, they provide efficient, safe, and durable performance even under the most demanding conditions.

Low-temperature self-regulating heating cables are designed to maintain temperatures up to 105 °C (221 °F).

They are ideal for freeze protection, pipe heating, tank and valve temperature maintenance, and domestic hot water systems.

Thanks to their PTC (Positive Temperature Coefficient) polymer core, the cable automatically adjusts its output power according to the ambient temperature, preventing overheating and reducing energy consumption.

Its flexible and durable structure allows for easy installation on different surfaces and lengths.

1. Freeze protection for pipes and storage tanks.

2. Temperature maintenance in fluid supply lines.

3. Roof, gutter, or ramp de-icing and heating systems.

Medium-temperature heating cables are designed for industrial applications requiring temperatures between 80 °C and 150 °C (176–302 °F).

They are widely used in production processes, transfer of viscous fluids, oils, or chemicals that need to maintain flow and thermal stability.

Constructed with fluoropolymer or PTFE insulation, they provide excellent chemical and mechanical resistance, ensuring long service life even in corrosive or chemical-exposed environments.

1. Industrial pipelines for oil, chemicals, or food products.

2. Thermal transfer and process heating systems.

3. Storage tanks and process valves.

High-temperature heating cables are engineered for demanding applications where temperatures up to 250 °C (482 °F) or higher are required.

These industrial heating tapes, made with fiberglass, fluoropolymer, or special silicone insulation, deliver stable and reliable performance under extreme heat conditions.

They are ideal for industrial process heating, steam lines, petrochemical systems, and power generation plants.

1. Heating of reactors, tanks, and steam pipelines.

2. Petrochemical and pharmaceutical processes.

3. Industrial equipment requiring high-temperature maintenance.

Product Name | Explosion-proof | Length of use per circuit | Holding temperature | Maximum temperature supported | Standard Power | Wide |

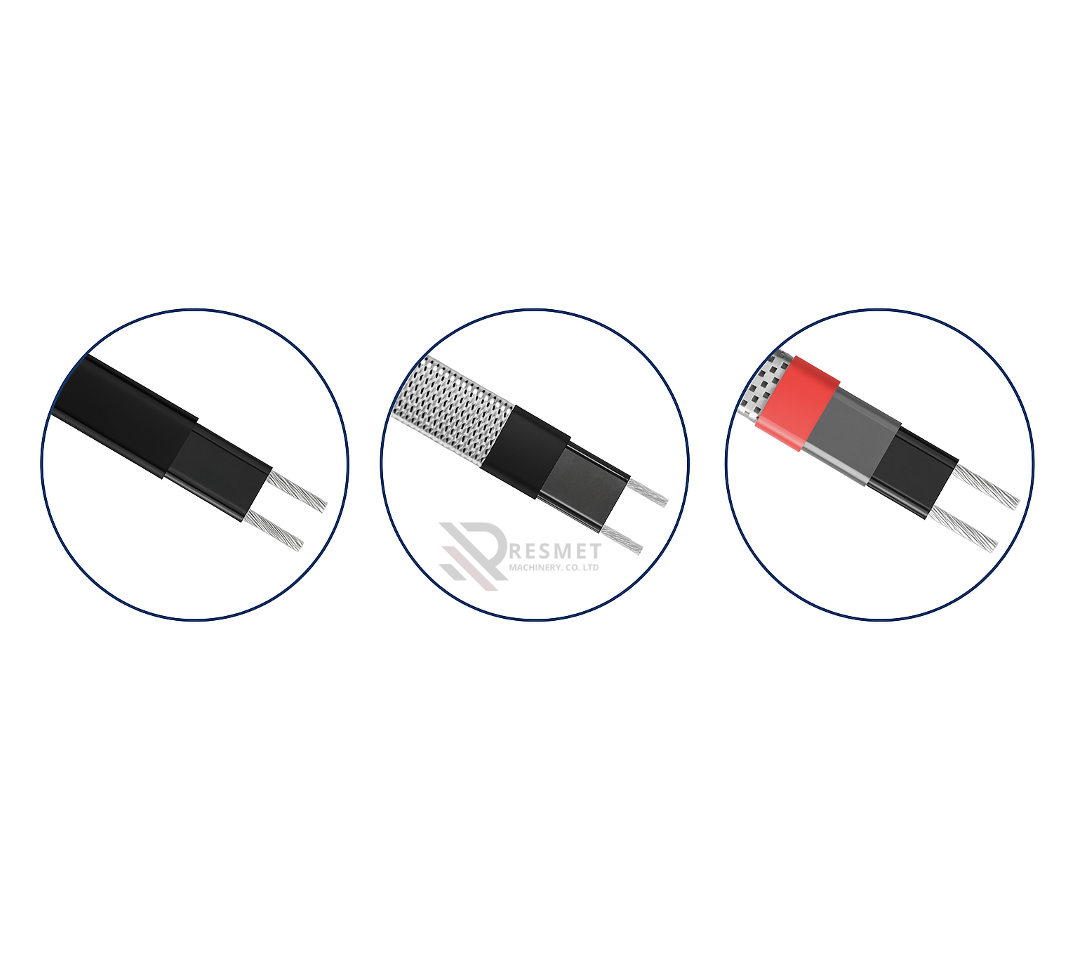

Basic Low Temperature Type | No | ≤100 m | 70°C | 105°C | 15W~35W | 11 mm |

Low Temperature Explosion Proof Type | Yes | ≤100 m | 70°C | 105°C | 15W~35W | 12 mm |

Reinforced low-temperature type | Yes | ≤100 m | 70°C | 105°C | 15W~35W | 14 mm |

Low temperature anti-corrosive type | Yes | ≤100 m | 70°C | 105°C | 15W~35W | 14 mm |

Basic type of medium temperature | No | ≤100 m | 105°C | 135°C | 35W~50W | 11 mm |

Medium Temperature Explosion Proof Type | Yes | ≤100 m | 105°C | 135°C | 35W~50W | 12 mm |

Medium Temperature Reinforced Type | Yes | ≤100 m | 105°C | 135°C | 35W~50W | 14 mm |

Medium temperature anti-corrosive type | Yes | ≤100 m | 105°C | 135°C | 35W~50W | 14 mm |

High temperature anti-corrosion type | Yes | ≤60 m | 120°C | 205°C | 50W~75W | 12 mm |

1. Energy efficiency: PTC self-regulating technology adjusts power output automatically.

2. Safety and durability: Made from high-quality, corrosion-resistant materials.

3. Flexible installation and easy maintenance.

4. Wide temperature range: Suitable for domestic, commercial, and heavy industrial applications.

5. Automatic temperature control without the need for an external thermostat.

6. High energy efficiency and long service life.

7. Customizable installation: Can be cut and spliced on-site according to project needs.

8. Resistant to moisture, corrosion, UV rays, and chemicals.

9. Compliant with strict safety and industrial protection standards.