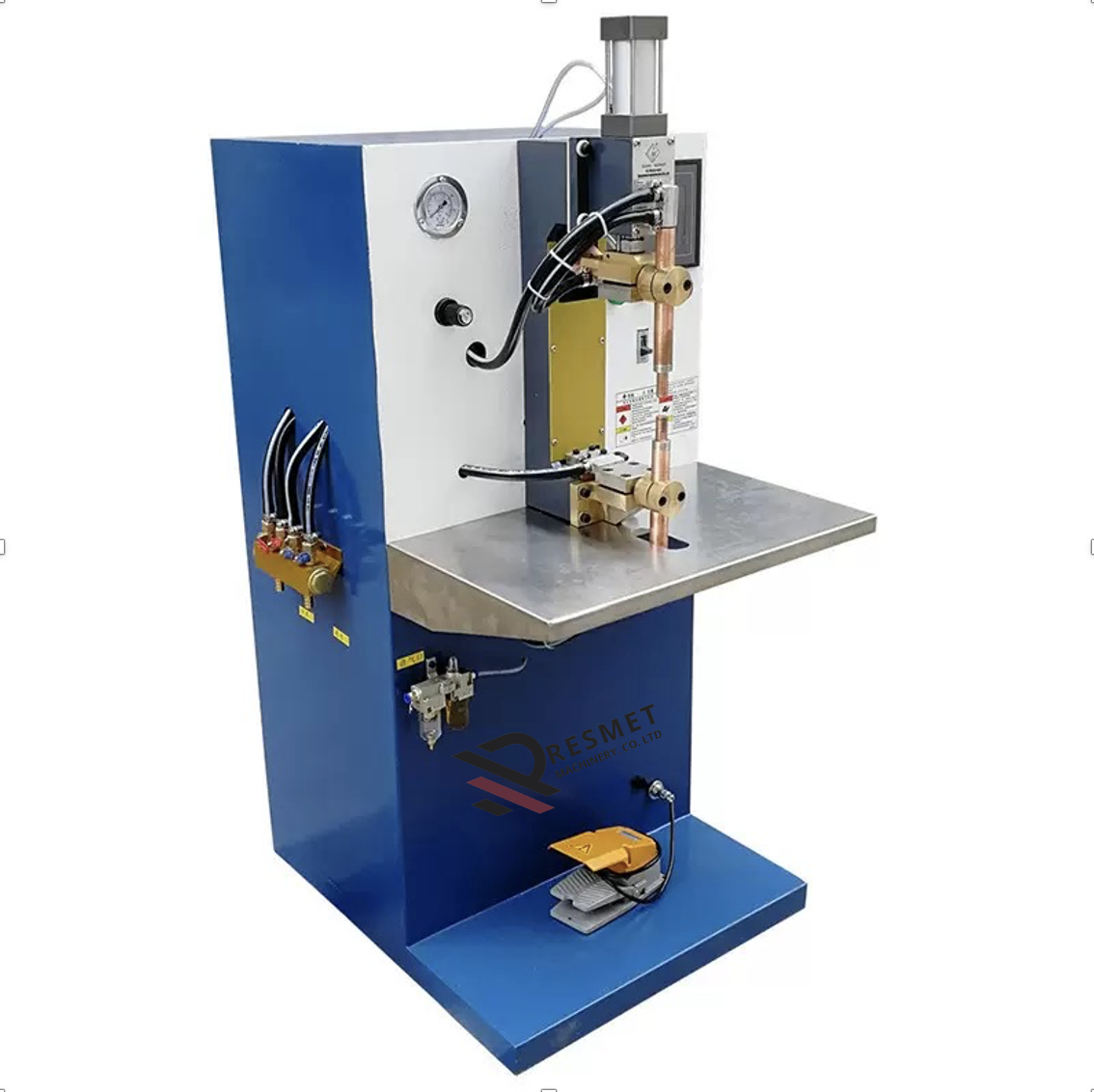

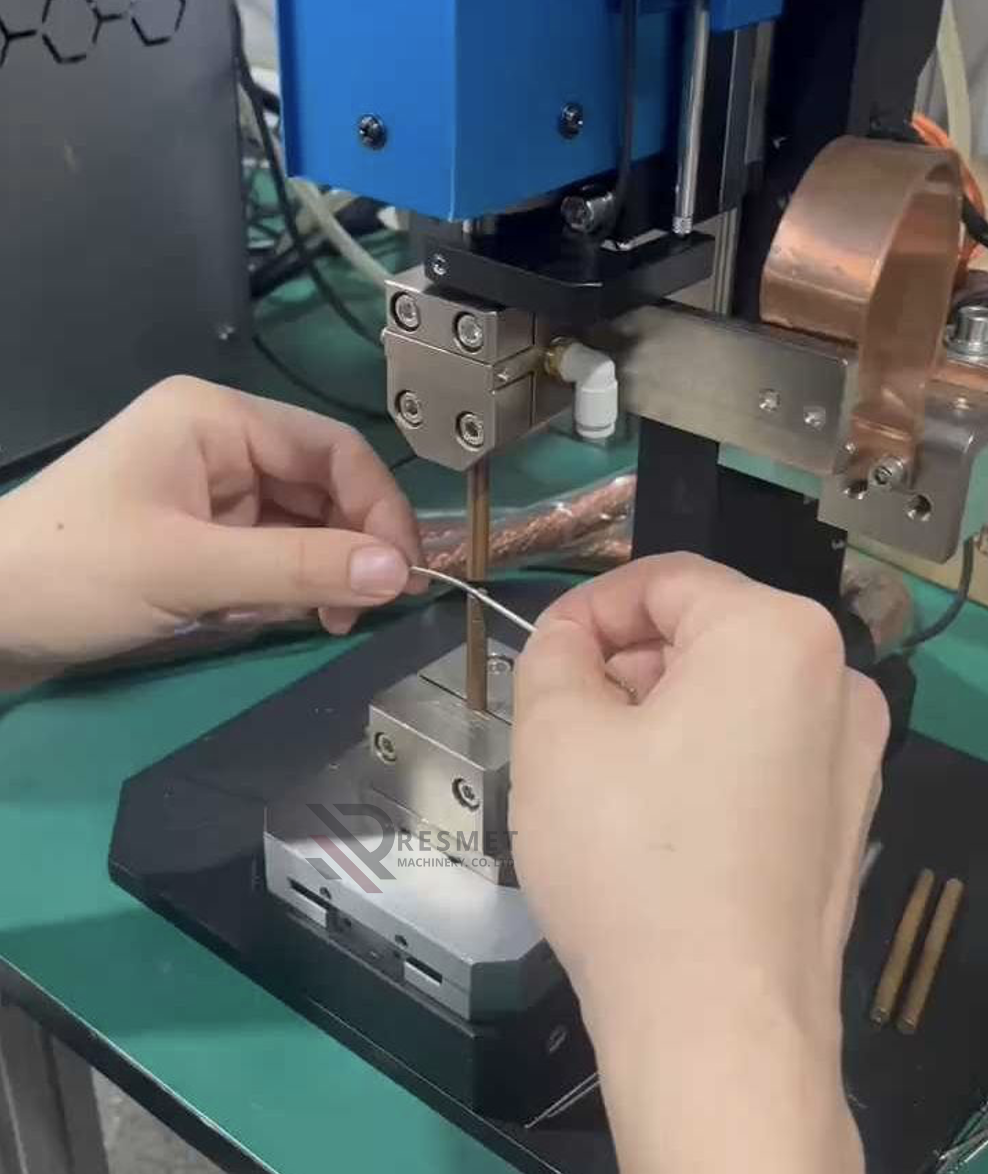

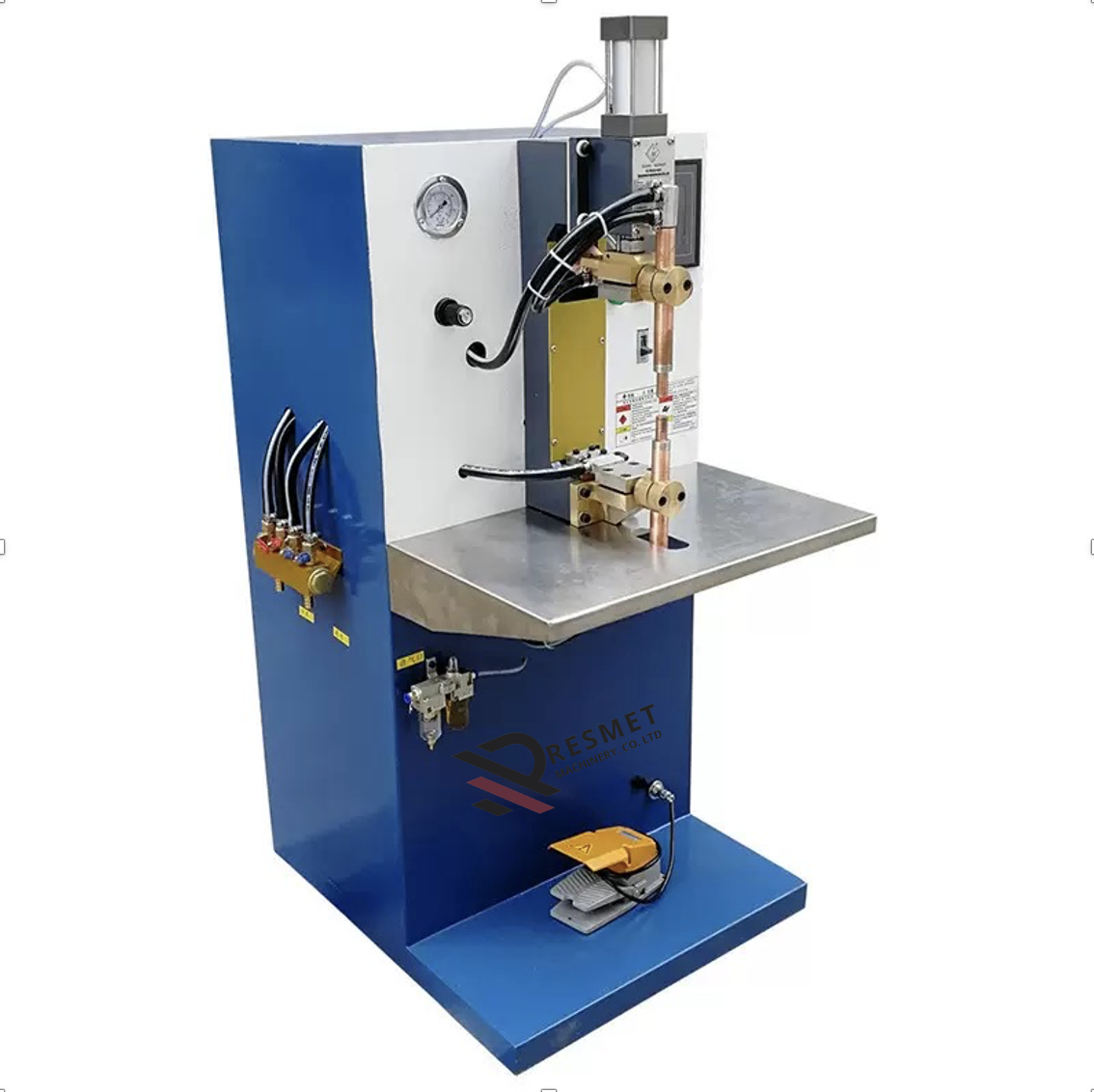

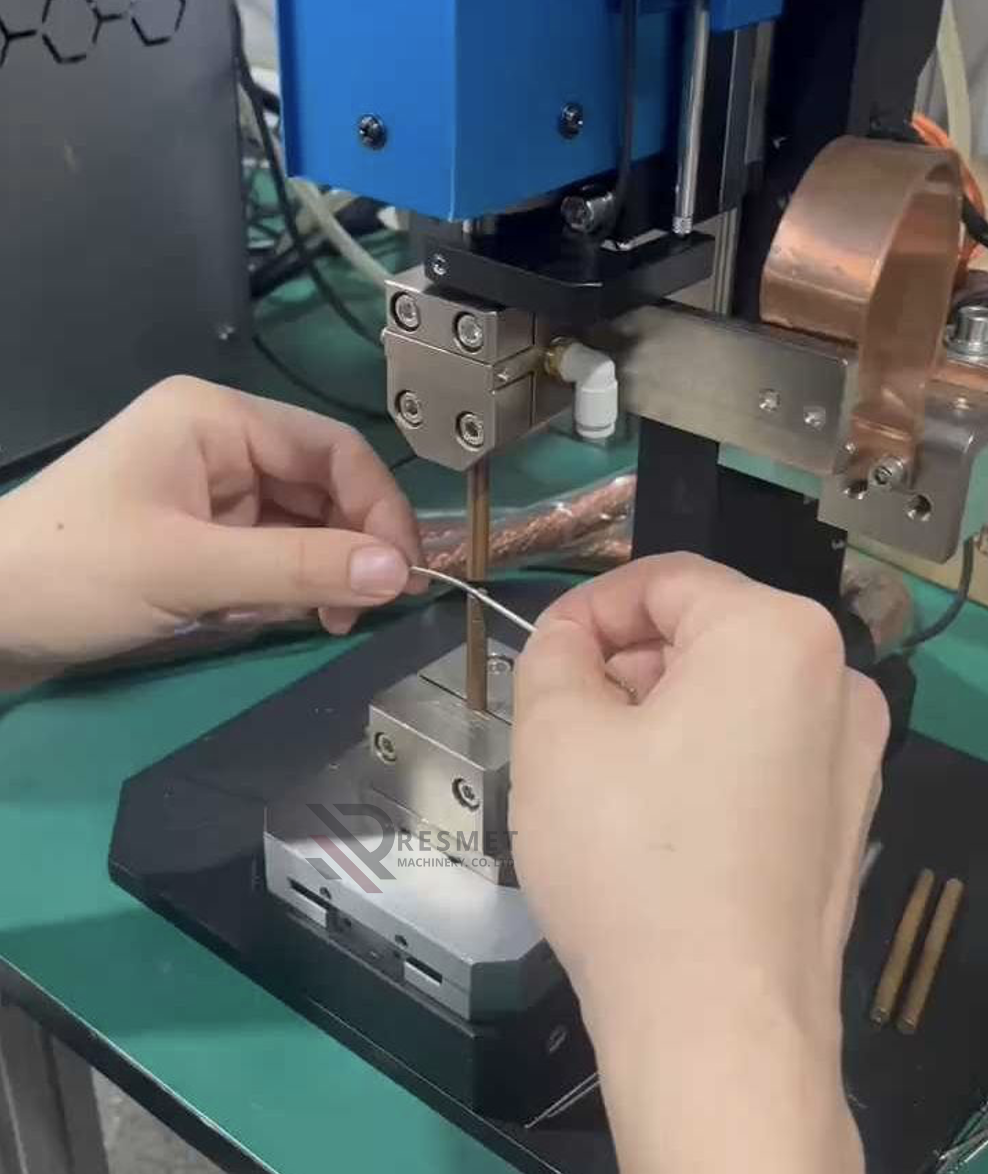

The RM-149A Pneumatic Spot Energy Storage Welding Machine is a specialized piece of equipment primarily designed for welding heating wires or coils to the terminals of electric resistors. This high-efficiency model is also ideal for welding resistance wires, lead posts, and lead terminals (lead bars). Its energy storage pneumatic system ensures precise, rapid welding with low energy consumption, making it an essential tool for manufacturers of electric resistors, heating elements, and heating products. The machine’s ergonomic design and ease of operation make it perfect for both novice and professional operators in the field of spot welding.

Heating wire welding: Specifically designed for welding heating wire or coils to electric resistor terminals.

Energy efficiency: Thanks to its energy storage system, the machine uses compressed air to perform rapid welds with low energy consumption.

High precision in spot welding: Guarantees precise welding on various conductive materials.

Ease of operation: Ideal for use by operators with basic or advanced experience in electric component welding.

Reliability and durability: High reliability for continuous use, making it ideal for industrial settings.

1. Model: RM-149A

2. Type: Pneumatic spot welding machine

3. Primary application: Welding of heating wire or coils to electric resistor terminals, welding resistance wires, lead posts, and lead terminals.

4. Operating voltage: Three-phase 380V/ Three-phase 220V/ Single-phase 220V

5. Rated power: 2 KVA

6. Welding method: Spot welding with energy storage pneumatic system

7. Welding capacity: High capacity for welding conductive materials with precision.

8. Working tension: Adjustable depending on the material and size of the parts to be welded.

9. Certification: Complies with international safety and quality standards.

10. Weight: Lightweight and easy to transport, suitable for large or small workspaces.

Low energy consumption: Optimizes energy use, reducing operational costs.

High welding speed: Increases productivity and efficiency in the production of electric resistors and heating components.

Durability and resistance: Robust construction that withstands long working hours and demanding industrial processes.

Simple maintenance: Its streamlined design makes maintenance easy and extends the machine’s service life.

Compatibility with various power sources: Works with multiple voltage configurations (380V, 220V, and single-phase).