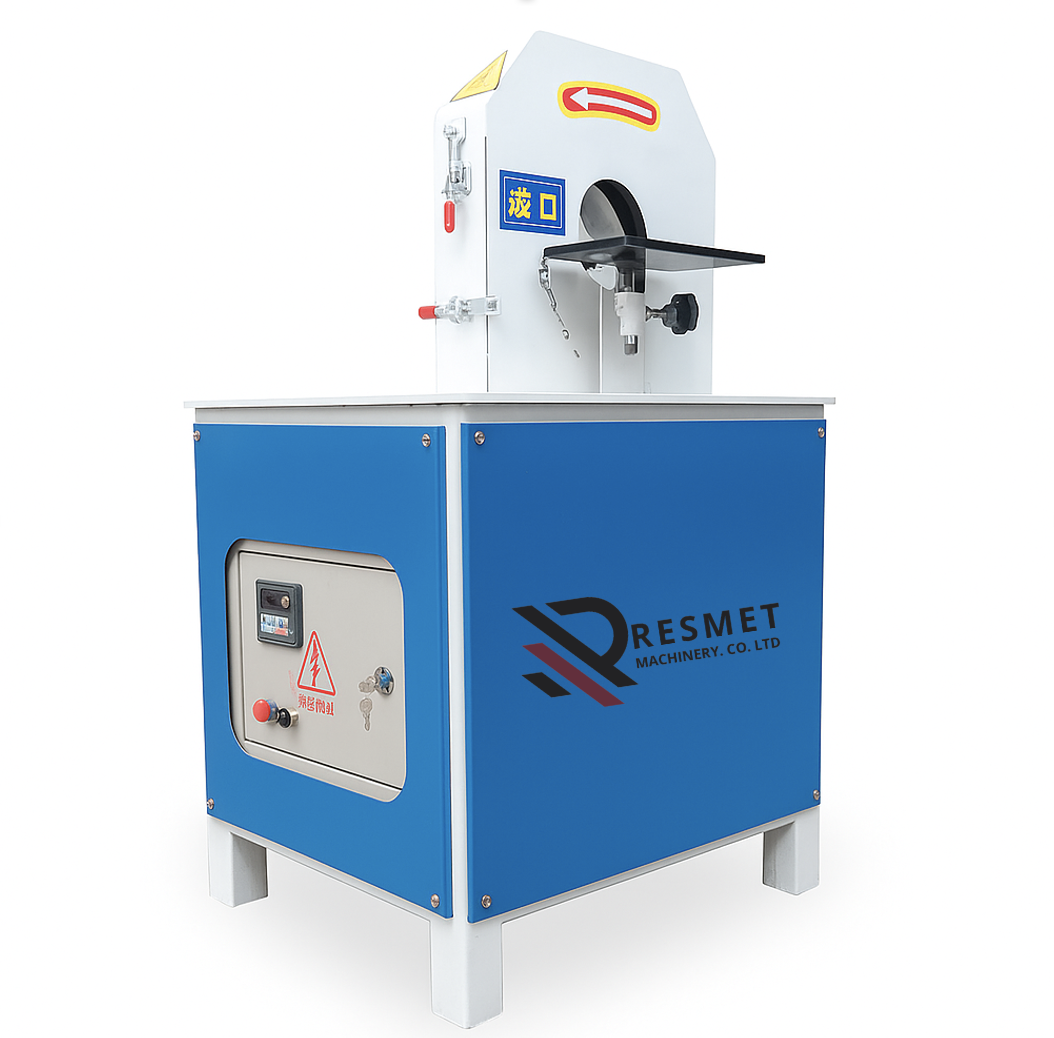

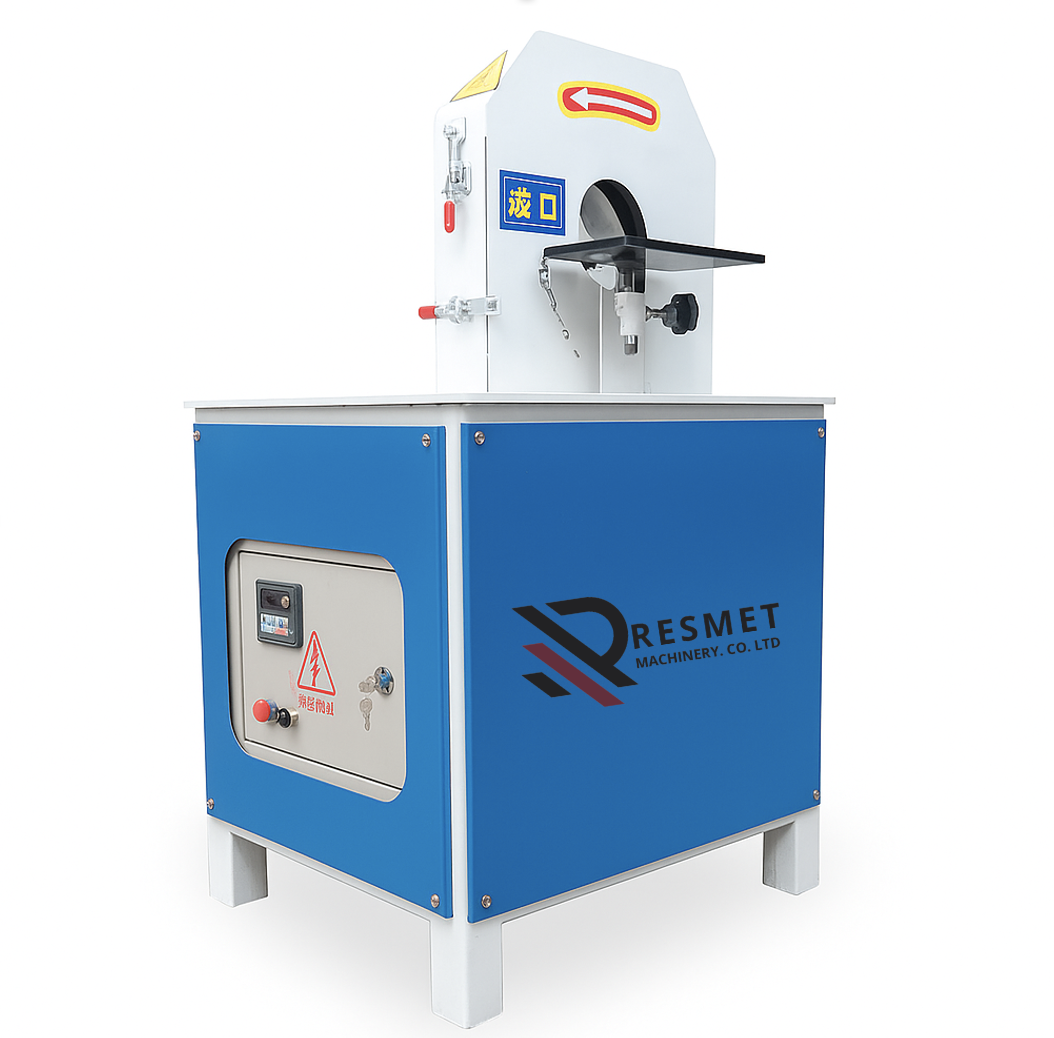

The curved tube polishing machine is a high-efficiency and high-precision industrial equipment, specially designed for sanding, polishing and mirror polishing of metal pipes, both straight and curved, round, flat or oval.

This automatic tube polisher is the ideal solution for professional, glossy and uniform finishes on a wide range of materials such as stainless steel, carbon steel, copper, aluminium, brass and non-ferrous metals.

Thanks to its advanced technology, the curved tube polisher allows for 360-degree polishing without the need to rotate the tube, ensuring a perfectly polished, homogeneous and mark-free surface. Its robust structure, stable performance, and ergonomic design ensure continuous, safe, and efficient operation in demanding industrial environments.

High precision 360° polishing: The system allows the entire surface of the tube to be polished without rotation, maintaining uniform pressure throughout the process.

Wide Shape and Material Compatibility: Ideal for curved, round, flat, and oval tubes, stainless steel, copper, aluminum, or carbon steel.

Flexible adjustment system: Allows you to regulate the pressure, speed and type of abrasive, adapting to different levels of finish: from satin or brushed polishing, to high gloss mirror polishing.

High energy efficiency: Powerful motor and optimized transmission system to reduce electricity consumption and maximize productivity.

Robust and durable structure: Made of industrial steel reinforced with long-lasting components.

Safe and easy operation: Includes digital control panel, emergency stop button and easy replacement of abrasive belts.

Minimal maintenance: Stable mechanical system and accessible design that makes it easy to clean and replace parts.

1. Model: RM110C

2. Applicable diameter: 5-250mm

3. Total power: 3KW/4KW

4. Production capacity: 1-12 m/min

5. Equipment dimensions: 800*800*1100 mm

6. Equipment weight: 230KG

Professional mirror polishing: Get high-quality surfaces with intense shine and uniform finish.

High speed and consistent performance: The metal tube polisher significantly improves productivity compared to manual polishing.

Compatible with different types of tubes: Efficient polishing of bent tubes, decorative tubes, structural tubes and design parts.

Integrated safety system: Prevents overheating and protects both the operator and the equipment.

Ergonomic and compact design: Ideal for workshops, factories and automated production lines.

Consistent results: Uniform polishing without deforming or damaging the tube surface.

Multiple finish options: Allows easy change of polishing tape to achieve from a brushed matte look to a glossy mirror finish.

The curved tube polishing machine is widely used in industrial and manufacturing sectors where high-precision finishes and professional aesthetics are required, such as:

1. Manufacture of metal furniture, railings, stairs, architectural structures and handrails.

2. Stainless steel industry, air conditioning components, heat exchangers and medical equipment.

3. Manufacture of kitchen equipment, metal decoration and industrial accessories.

4. Polishing of copper and aluminum tubes for electrical, thermal or ornamental applications.

5. Automotive and aerospace industry, where the quality of the finish is essential.