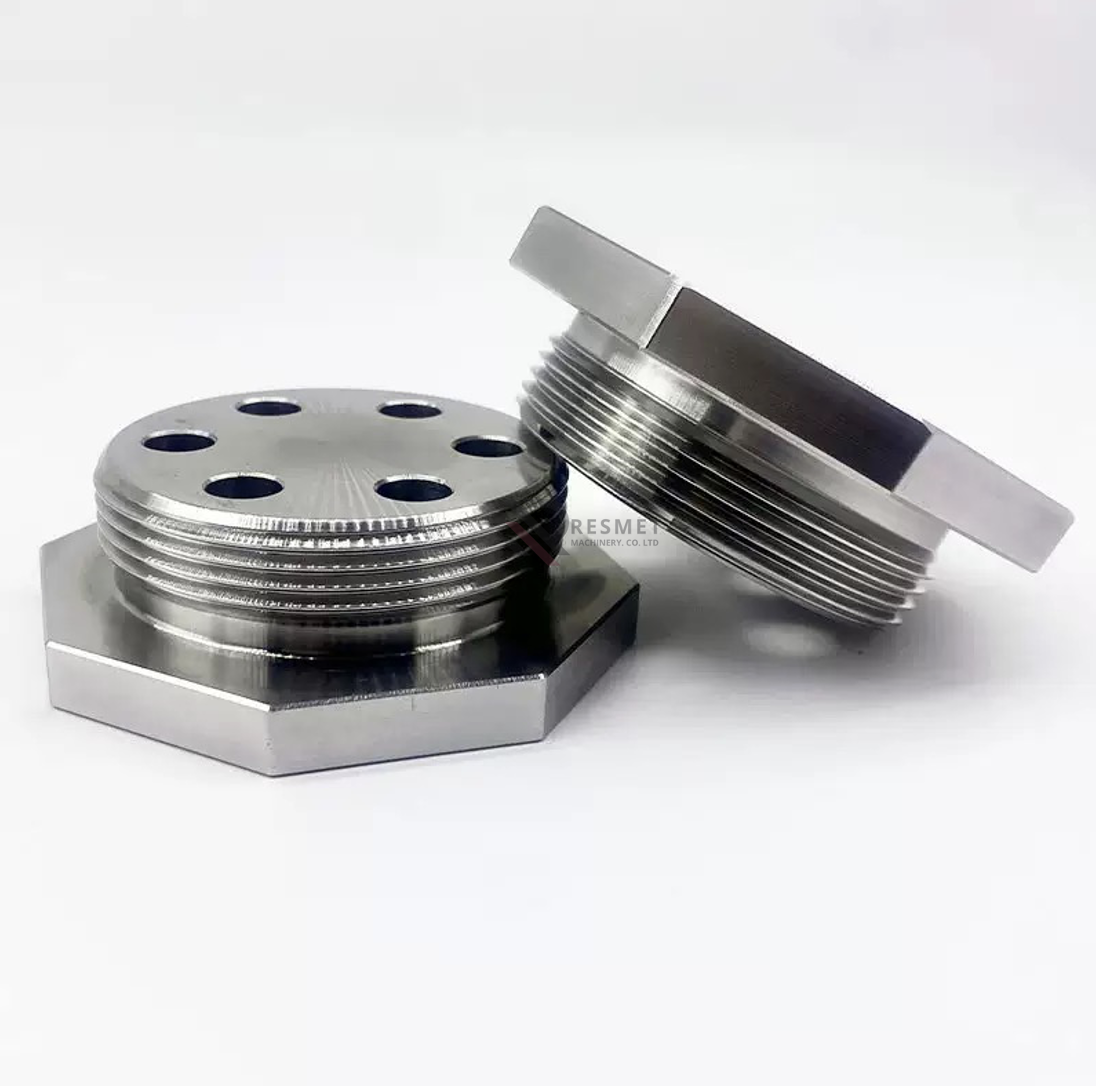

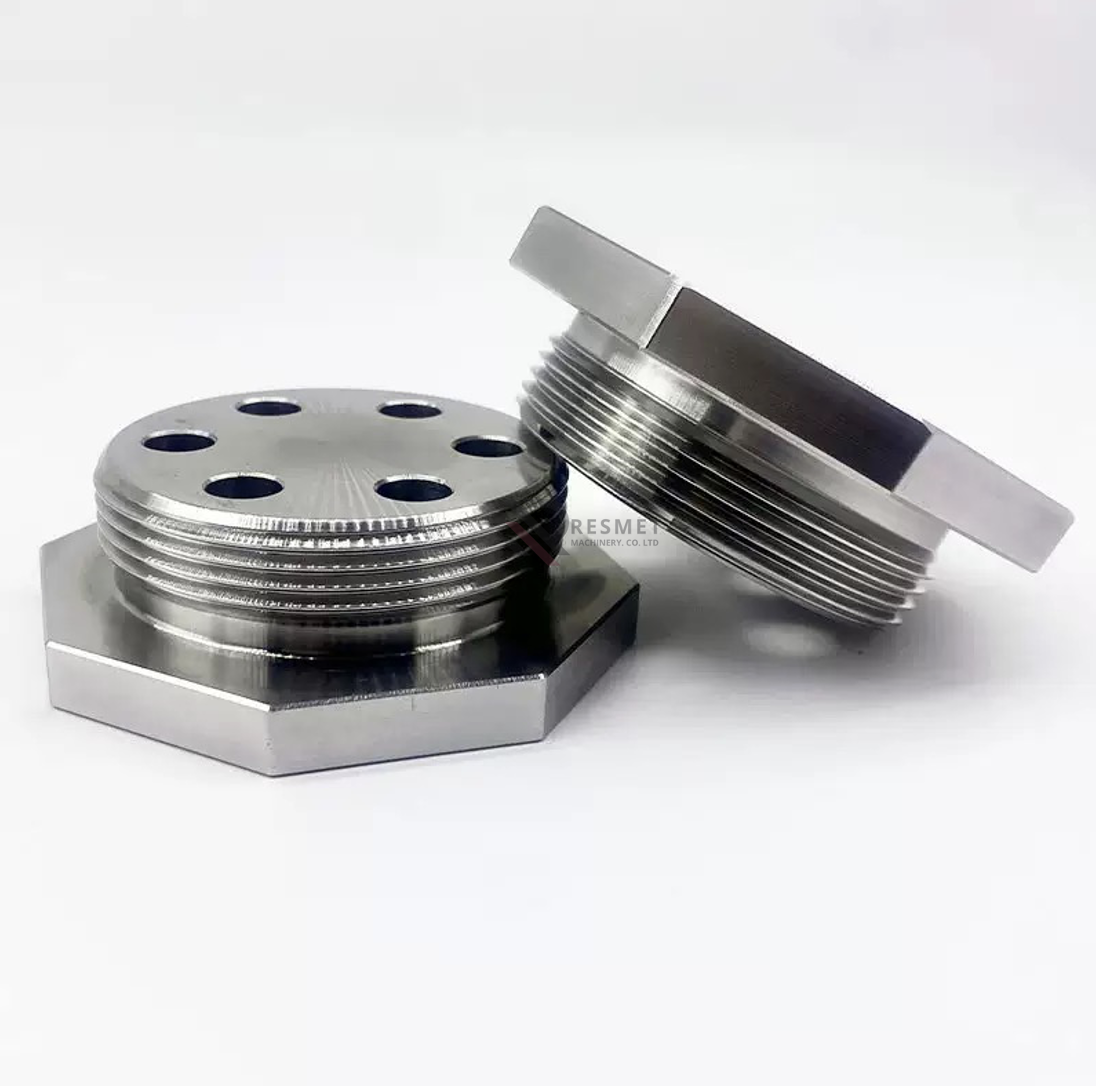

Flanges for Electric Heaters are essential components used to connect immersion heaters, tubular heating elements, thermocouples, pipes, valves, pumps, industrial accessories, and equipment such as filters and pressure vessels. These connections can be welded or threaded, and two flanges are joined with bolts and gaskets to ensure a reliable seal and easy system access.

These heater flanges are designed to withstand high pressure and high temperature, making them suitable for demanding industrial applications. For this reason, different pressure ratings and materials are available.

Our product range includes:

Flange for Electric Heaters, Flange for Thermocouples, Flange for Cartridge Heaters, Flat Flange for Heating Elements, Custom Flanges, Integral Flange, Threaded Flange, Flat Weld Flange, Weld Neck Flange, among others.

We also manufacture special flanges, prototypes, and custom designs for unique applications.

The BSP standard is widely used across Europe, Asia, and Latin America. It features:

• A 55° thread angle

• Versions BSPP (parallel) and BSPT (tapered)

• Excellent performance in hydraulic, pneumatic, and thermal systems

• Compatibility with multiple industrial fittings

The NPT standard is predominant in North America and features:

• A 60° thread angle

• Exclusively tapered threads for a pressure-tight seal

• Ideal for high-pressure and high-temperature applications

• Commonly used in petrochemical, heating, and industrial equipment

The choice between BSP and NPT depends on system compatibility, mechanical resistance, pressure requirements, and regional standards.

1. Product name: flanges for heaters

2. Material: Brass, Carbon Steel, Stainless Steel: 304, 316L, Duplex, Super Duplex, Special Alloys (upon request).

3. Connection type: Flange or threaded

4. Power (W): Adapted to the power density (W/cm²) required for the fluid and volume

5. Voltage (V): From 24V to 600V or more.

6. Available Dimensions: 1/4”, 3/8”, 1/2”, 5/8”, 3/4”, 7/8”, 1” , 1 1/4”, 1 1/2”, 2”, 2 1/2”, 3”

We offer Custom Flanges according to detailed specifications, prototypes, industrial batches, and special designs for cartridge heaters, thermocouples, immersion systems, and thermal equipment.