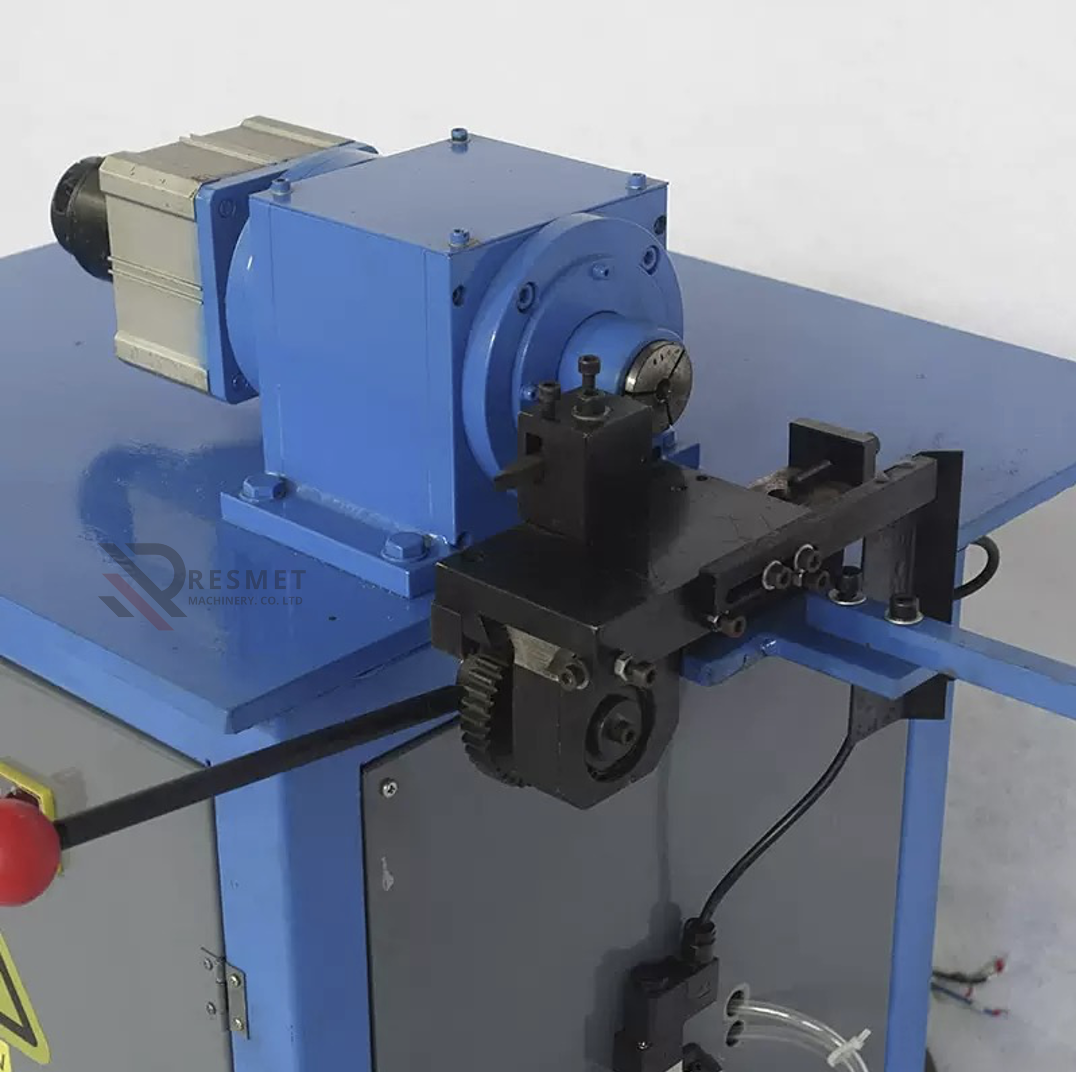

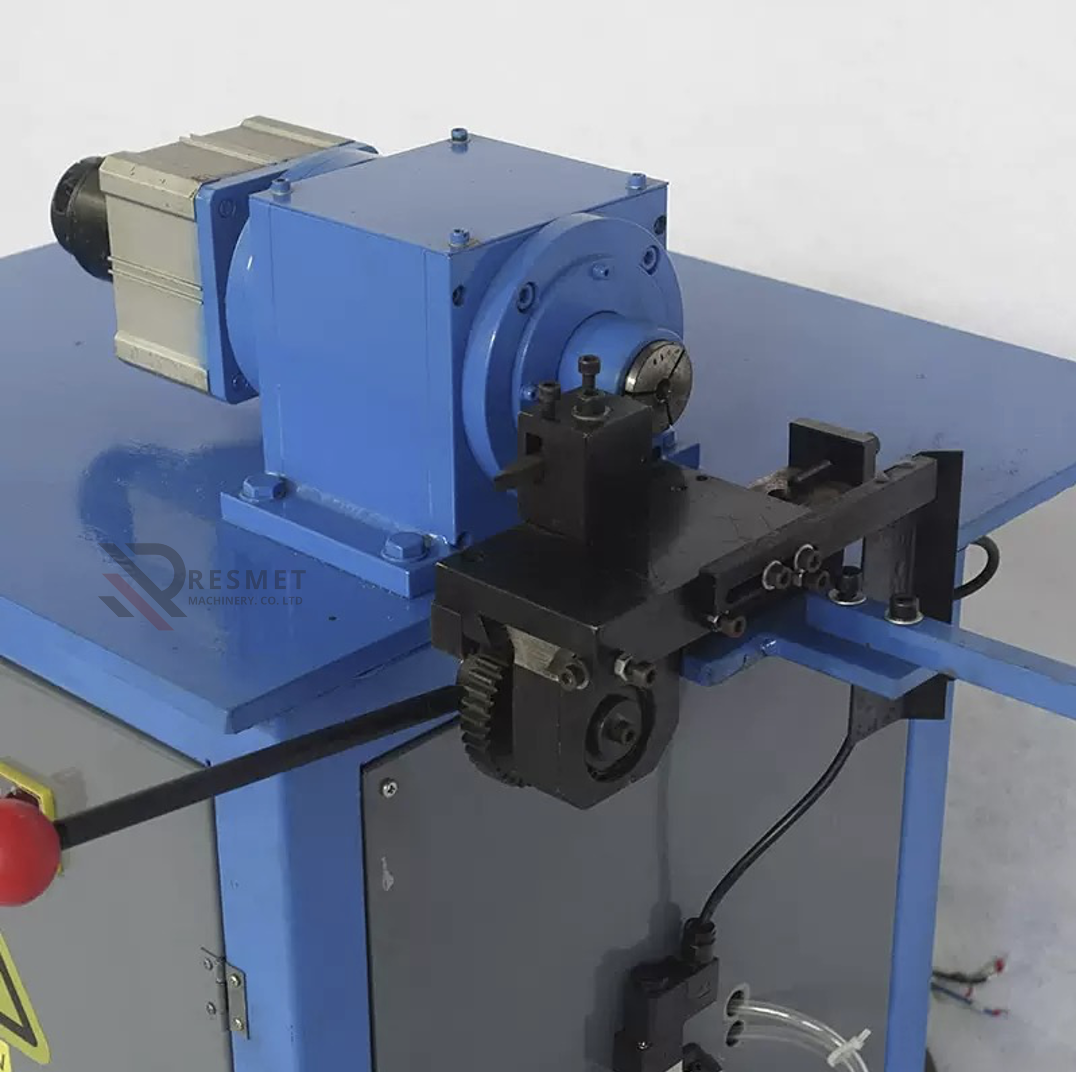

The RM-101B Manual Pipe Cutting Machine is a semi-automatic pipe cutting system designed for high-precision cutting of pipes of various diameters and lengths. Equipped with an elastic chuck clamping system, it allows quick and easy size changes, improving work efficiency and accuracy.

This model is ideal for small-batch and multi-specification production, making it a great choice for metal processing, plumbing, and manufacturing industries.

The RM-101B is capable of cutting carbon steel, stainless steel, copper, aluminum, brass, PVC, and other metallic and non-metallic materials, delivering consistent performance and smooth cutting finishes.

Its compact and durable structure, combined with a 0.75KW motor, ensures stable operation and long service life — perfect for workshops and industrial production lines requiring clean and accurate cuts.

Parameter | Details |

Model | RM-101B |

Type | Semi-automatic manual pipe cutting machine |

Applicable Pipe Diameter (mm) | 3 – 30 |

Applicable Pipe Length (mm) | 50 – 6000 |

Production Quantity (pcs per shift) | 6000 – 15000 |

Cutting Speed | Constant speed |

Feeding Method | Manual |

Motor Power | 0.75 KW |

Voltage Options | Three-phase 480V / 380V / 220V / Single-phase 220V |

Air Pressure Requirement | 0.6 MPa |

Machine Dimensions (mm) | 1500 × 800 × 1200 |

Machine Weight | 200 KG |

1. Fast and precise cutting for a wide range of materials.

2. Quick diameter change using elastic chucks.

3. Compact and heavy-duty design for industrial environments.

4. High efficiency in small-batch production.

5. Compatible with multiple industrial voltage systems.