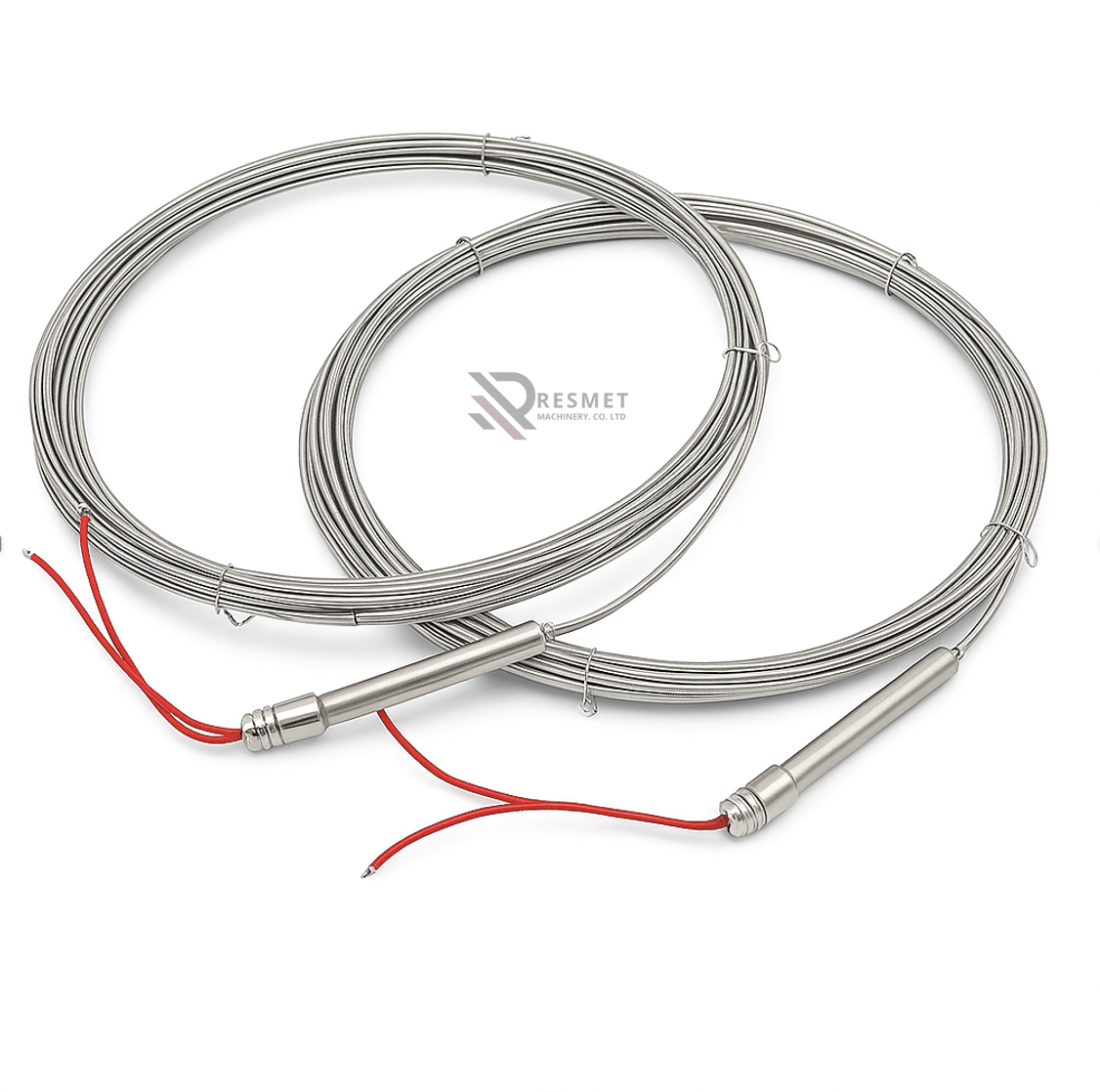

The Mineral Insulated Heating Cable (MI type) is a high-performance armored electrical cable designed for use in high-temperature, corrosive, humid or fire-exposed environments where conventional cables cannot operate safely.

It consists of metal conductors (typically copper, copper-nickel, or nickel-chrome alloys) insulated with high-purity magnesium oxide (MgO) and protected by a metallic sheath that provides excellent mechanical strength and environmental protection.

Thanks to its unique inorganic construction, the MI cable offers exceptional thermal stability, superior electrical insulation, and a service life exceeding 30 years, even under continuous high-temperature operation.

1. FF: SUS304/SUS316L/SUS310S/Inconel600/Inconl825

2. Heating core wire: Kanthal Cr20Ni80/NCHW-1

3. Wire: pure nickel wire/copper tin-plated

4. Diameter: 1.0~8.0/Others Support single-piece customization

5. Length: 30mm~100,000mm/Others Support single-piece customization

6. Voltage: 208V/220V/380V/Other

7. Power: 3W~200W/m Other working temperature: ≤650°C

8. Power frequency withstand voltage: ≥1500V/min

9. Insulation Resistance: ≥100M2

10. Thermal leakage current: ≤10mA

Inner Conductors: Copper, copper-nickel, or nickel-chromium alloys.

Insulation: High-purity (> 99%) magnesium oxide (MgO) mineral powder.

Outer Sheath: Copper, stainless steel (SS304, SS316, SS321, SS310), Inconel, or Alloy 825.

Optional Outer Jacket: HDPE, PVC, or LSZH (Low Smoke Zero Halogen) for extra protection against moisture or chemical corrosion.

This combination provides outstanding thermal conductivity, electrical integrity, and resistance to oxidation, moisture, and mechanical impact — even at extremely high temperatures.

Operating temperature range: –40 °C to +250 °C (standard versions).

Maximum exposure temperature: up to +1000 °C (depending on sheath material).

Dielectric strength: ≥ 15 kV/mm.

Tensile strength: ≥ 200 N.

Power output: typically between 50 W/m and 300 W/m depending on design.

Nominal voltage: 230 V to 600 V.

Minimum bending radius: 6 × cable outer diameter.

Expected service life: over 30 years under proper installation.

The cable’s mineral insulation ensures excellent dielectric resistance, low leakage current, and stable electrical performance even in humid or corrosive environments.

The MI mineral insulated heating cable offers multiple advantages compared to conventional polymer-insulated cables:

Fire resistance: maintains circuit integrity during prolonged fire exposure.

Thermal stability: MgO insulation remains stable even at extreme heat.

Exceptional durability: immune to aging, UV, moisture, and chemical degradation.

High mechanical and chemical resistance: ideal for heavy-duty and corrosive environments.

Excellent heat transfer: ensures efficient and uniform heating.

Safe operation: non-flammable, halogen-free, and emits no toxic gases.

Maintenance-free: once installed, it requires virtually no service.

The MI mineral insulated heating cable is suitable for numerous industrial and commercial uses, including:

Tubular and cartridge electric heaters used in furnaces, molds, boilers, and heat exchangers.

Electrical heat tracing systems for process pipes, tanks, and valves.

Temperature sensors and thermocouples for harsh or high-temperature environments.

Fire-resistant power circuits in tunnels, refineries, power plants, and offshore platforms.

Industrial and process heating systems requiring reliability and long life.

Hazardous and corrosive environments certified under ATEX and IECEx standards.

To guarantee the best performance, MI cables should be installed following these recommendations:

1. Keep cable surfaces clean and dry to prevent moisture absorption by the MgO insulation.

2. Respect the minimum bending radius (at least six times the cable’s outer diameter).

3. Avoid twisting, striking, or over-bending during installation.

4. Use proper sealing and termination kits to prevent moisture ingress into the cable ends.

5. In outdoor or wet areas, apply an additional protective over-jacket for extended service life.

Correct installation ensures maximum electrical reliability, insulation resistance, and heating efficiency.

MI heating cables provide stable, uniform heat output and allow precise temperature control across long lengths.

Their excellent thermal conductivity ensures minimal temperature drop and high energy efficiency.

These cables can continuously operate at temperatures up to 600 °C and withstand short-term peaks of 800 °C to 1000 °C without losing electrical properties.

Because the insulation is inorganic, no degradation, softening, or outgassing occurs, making MI cables ideal for continuous or cyclic heating applications.

The mineral insulated cable is virtually maintenance-free once installed.

However, periodic inspection of terminations and seals is recommended to ensure long-term insulation integrity.

Avoid prolonged exposure to water before sealing, since magnesium oxide is hygroscopic and may absorb moisture if unprotected.

The metallic sheath should always be properly grounded to enhance electrical safety.