Magnesium oxide powder (MgO) low, medium and high temperature

RM-H series is a high-temperature magnesium oxide powder with silicon-free surface treatment or with a light silicon surface treatment. It is divided into four grades and specifications based on various electrical performance requirements. It is suitable for the production of various high-temperature electric air heating elements. It withstands high-temperature heat treatments (such as annealing at 1050°C) and has excellent electrical properties, but is not resistant to moisture. Products must be sealed in time after dehumidification.

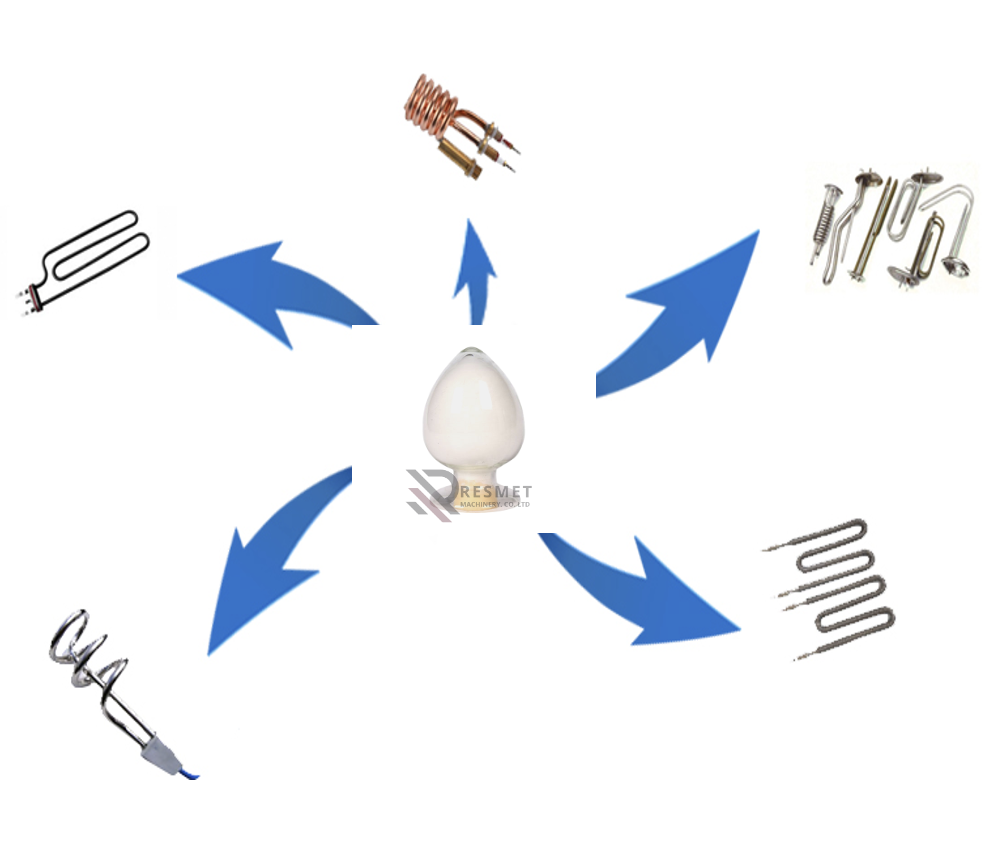

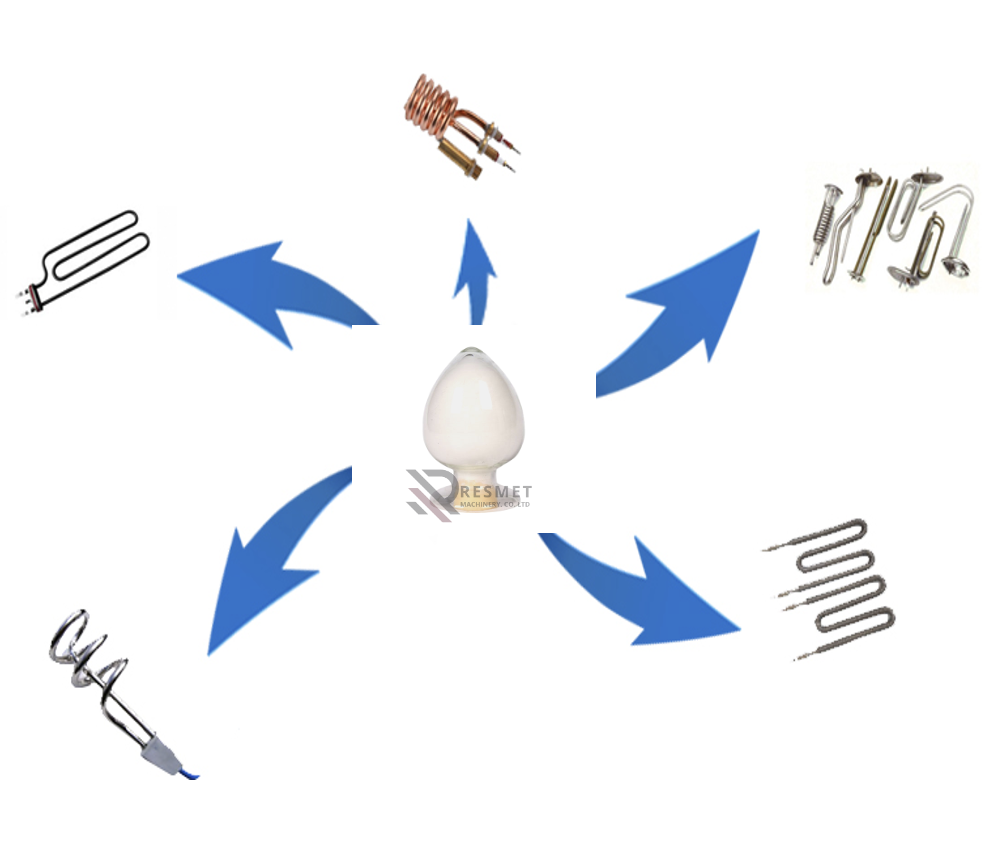

Suitable for: electric air conditioning heaters, immersion or water heaters, cartridge heaters, oven heaters, anti-mosquito coil heaters, defrost heaters, washing machine heaters and other medium or high temperature air heating elements, both civil and industrial.

Specs & Models | Chemical Analysis % | Magnetics ppm | Sulphur S ppm | Carbon C ppm | |||||

MgO | CaO | AI2O3 | FE2O3 | SiO2 | LOI | ||||

RM-H9 | ≧ 97 | ≦1.0 | ≦ 0.9 | ≦ 0.4 | ≦1.5 | ≦0.04 | ≦ 30 | ≦ 10 | ≦ 10 |

RM-H8 | ≧96.5 | ≦1.5 | ≦ 0.9 | ≦ 0.5 | ≦2.0 | ≦0.04 | ≦ 40 | ≦ 10 | ≦ 10 |

RM-H7 | ≧ 95 | ≦2.0 | ≦ 0.9 | ≦ 0.6 | ≦2.5 | ≦0.08 | ≦ 50 | ≦ 10 | ≦ 10 |

RM-H6 | ≧ 93 | ≦2.0 | ≦ 0.9 | ≦ 0.6 | ≦3.5 | ≦0.08 | ≦ 100 | ≦ 10 | ≦ 10 |

Mesh | +40 | +60 | +80 | +140 | +200 | +325 | -325 |

Particle size (mm). | +425 | +250 | +180 | +106 | +75 | +45 | -45 |

Content (%) | ≦ 0.5 | 26 ± 6 | 25 ± 6 | 25 ± 6 | 12 ± 5 | 11 ± 5 | 5 ± 5 |

Note: The +425 mm and -45 mm levels are strictly controlled within the specified ranges, and in order to obtain the required intake and flow rate, other mesh levels may exceed the above ranges. (Special requirements, can be produced according to customer's needs).

PT (g/cm3): 2.30-2.45 |

Flow rate F.T. (s/100g) : 38 ± 6 |

Flow rate FR. (s/100g) : 165 ± 20 |

Specs & Models | Chemical Analysis % | ||||||||

Under normal condition | Hot with current leakage (mA) | ||||||||

isolation MΩ | Pressure resistant V/1mA | 5W/cm2 | 6W/cm2 | 7W/cm2 | 8W/cm2 | 9W/cm2 | 10W/cm2 | 11W/cm2 | |

RM-H9 | ≧ 1000 | ≧ 2500 | 0.02 | 0.025 | 0.03 | 0.07 | 0.12 | 0.20 | 0.40 |

RM-H8 | ≧ 1000 | ≧ 2500 | 0.03 | 0.04 | 0.05 | 0.08 | 0.18 | 0.30 | 0.50 |

RM-H7 | ≧ 1000 | ≧ 2500 | 0.04 | 0.06 | 0.10 | 0.15 | 0.25 | 0.40 | ---- |

RM-H6 | ≧ 1000 | ≧ 2500 | 0.05 | 0.08 | 0.18 | 0.24 | 0.50 | ---- | ---- |

RM-H series products are the latest high-temperature magnesium oxide special products developed and produced by our company. After years of market launch, they have received unanimous praise from domestic and international customers who manufacture high-temperature electric heating elements. They are suitable for the production of all types of electric heating elements with temperatures below 1200 °C and withstand high-temperature heat treatments (such as annealing at 1050 °C). These products are manufactured using high-quality molten magnesia as raw material and processed by incorporating foreign advanced process technology. Compared with domestic high temperature electric grade magnesium oxide products, they offer the following quality advantages:

Low magnetic content: Most domestic manufacturers are between 200ppm~600ppm, while the company's high-temperature electric-grade magnesium oxide H-series special products have ≤60ppm; The lower magnetic content is conducive to improving the service life of the electric heater, and the service life can be increased by more than 20% according to the shape test.

Low moisture content (LOl): That is, low moisture content, average household ordinary products are generally ≥ 0.08%, or even more (more than 0.1%), while our special series of high temperature H electric grade magnesium oxide is only less than 0.04%.

This index is conducive to the moisture discharge treatment of the electric heating element, and for the long pipe, it can be easy to drain the moisture and prevent the expansion of the pipe in the heat treatment.

Lower hydration rate: The lower the hydration rate of magnesium oxide, the lower the moisture absorption of magnesium oxide, resulting in slower absorption of magnesium oxide.

Low sintering index: it is manifested in the electrical resistance that the degree of decay of high voltage by bending is lower (compared to ordinary products), which favors the improvement of the compressive strength of the electric heating element.

No organic impurities: It can prevent carbonization and blackening of organic matter in the heat treatment process of the heating element due to organic impurities that can creep into magnesium oxide.

Better electrical performance: In general, compared with products of the same level, the electrical performance of this product is better; When applied to pipes over 2.5 meters long, the test data is better, and the insulation resistance and voltage resistance improve significantly year after year.

This product has uniform color, good particle shape, beautiful appearance, and small dust grain, which is conducive to improving the dust adding environment .

Electrical-grade magnesium oxide powder is non-toxic and features a small amount of dust. It is recommended to wear a mask and gloves during use. The product should be stored in a dry place and is recommended for use within 12 months of leaving the factory.