Incoloy alloys are nickel-iron-chromium-based materials engineered to perform exceptionally in high-temperature and high-corrosion environments. Their optimized balance of nickel (Ni), chromium (Cr), and iron (Fe) delivers superior resistance to:

· Oxidation and carburization

· Pitting and crevice corrosion

· Stress Corrosion Cracking (SCC)

· Sulfidation and intergranular attack

These tubes are widely used across oil & gas, chemical processing, power generation, marine desalination, pharmaceuticals, and heat exchanger systems.

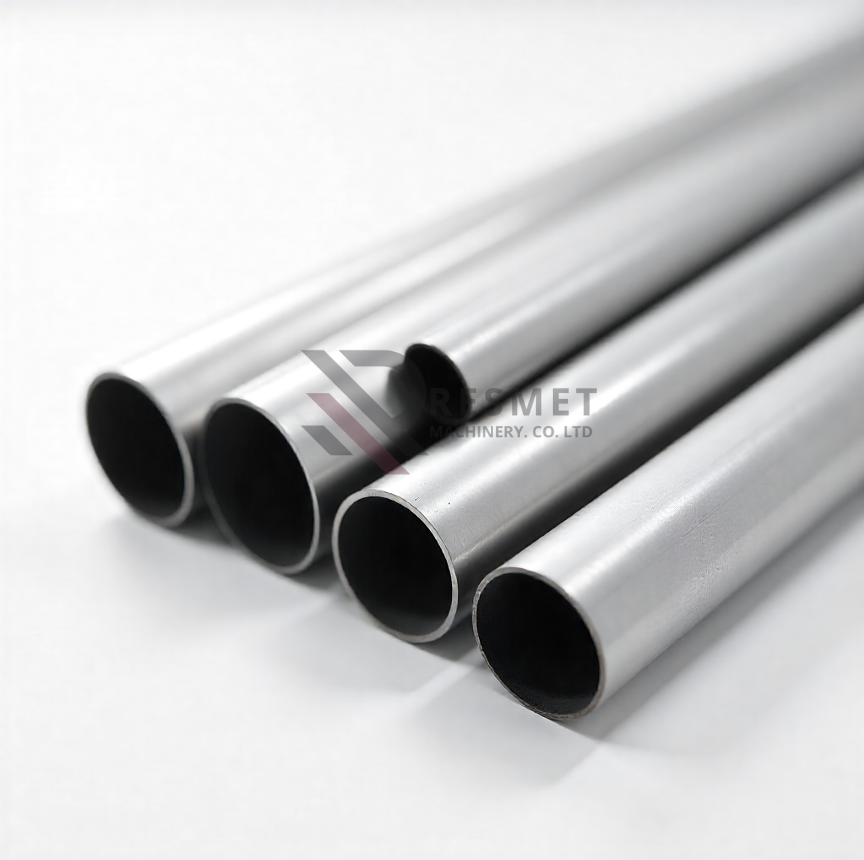

Available forms: Seamless tubes, welded tubes, coiled tubing

Surface finishes: Bright Annealed (BA), Pickled, Polished, Bead Blasted, Mirror Finish

Standards: ASTM, ASME, EN, DIN, ISO

Certifications: ISO 9001, EN 10204 3.1 / 3.2, PED 2014/68/EU

High Corrosion Resistance → Protects against acids, alkalis, seawater, and chlorides

Excellent High-Temperature Performance → Up to 1150°C (Incoloy 840)

Superior Mechanical Strength → Maintains stability under high-pressure and thermal cycling

Good Fabrication & Weldability → Compatible with GTAW, GMAW, SMAW, and SAW processes

Long Service Life → Lower maintenance costs in aggressive environments

Alloy | UNS | Service Temp | Standards | Key Advantages |

Incoloy 825 | N08825 | Up to 540°C | ASTM B423 / SB423 | Exceptional resistance to acids, SCC, and seawater |

Incoloy 800 | N08800 | Up to 1100°C | ASTM B407 / SB407 | Resists oxidation and carburization at elevated temps |

Incoloy 800H | N08810 | Up to 1100°C | ASTM B407 / SB407 | Higher creep-rupture strength for pressure vessels |

Incoloy 840 | S33400 | Up to 1150°C | ASTM A312 / A213 | Ideal for heaters, furnaces, and high-temp exchangers |

Incoloy 926 | N08926 | Up to 400°C | ASTM B677 / SB677 | Superior pitting resistance in chloride-rich environments |

Alloy | Ni (%) | Cr (%) | Fe (%) | Mo (%) | Cu (%) | Ti (%) | Others |

825 | 38–46 | 19.5–23.5 | Balance | 2.5–3.5 | 1.5–3.0 | 0.6–1.2 | C ≤ 0.05 |

800 | 30–35 | 19–23 | Balance | – | – | 0.15–0.6 | Al ≤ 0.6 |

800H | 30–35 | 19–23 | Balance | – | – | 0.25–0.6 | C=0.05–0.10 |

840 | 18–20 | 18–20 | Balance | – | – | – | C ≤ 0.08 |

926 | 24–26 | 19–21 | Balance | 6–7 | 0.5–1.5 | – | N=0.15–0.25 |

Alloy | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Hardness (HB) |

825 | ≥220 | ≥550 | ≈30 | ≤200 |

800 | ≥205 | ≥520 | ≈35 | ≤200 |

800H | ≥210 | ≥530 | ≈30 | ≤200 |

840 | ≈250 | ≈600 | ≈25 | ≤220 |

926 | ≥300 | ≥650 | ≈35 | ≤230 |

Property | 825 | 800/800H | 840 | 926 |

Density (g/cm³) | 8.14 | 7.94 | 7.90 | 8.05 |

Thermal Conductivity (W/m·K) | 11.2 | 14.5 | 12.0 | 11.8 |

Coefficient of Expansion (µm/m·K) | 14.0 | 13.9 | 13.6 | 13.0 |

Melting Range (°C) | 1370–1400 | 1357–1385 | 1370–1410 | 1350–1400 |

1.Chemical & Petrochemical: Heat exchangers, reactors, scrubbers

2.Oil & Gas: Downhole tubing, offshore platforms, sour service pipelines

3.Power Generation: Superheaters, reheaters, boiler tubes

4.Desalination & Marine: Evaporators, brine heaters, condensers

5.Pharmaceuticals & Food: High-purity processing equipment

6.Aerospace & Automotive: Turbochargers, exhaust manifolds, high-performance piping

· Specify: Alloy, OD, wall thickness, length, finish, form (seamless/welded)

· Delivery: Cut-to-length up to 12 meters or coils up to 100 meters

· Lead Times: 7–30 days depending on stock and customization

· Packaging: Export-ready, seaworthy bundles with protective end caps